When using the Ultrasonic Sensors, what precautions are necessary for the surrounding environment?

Do not use the Ultrasonic Sensors at a temperature exceeding the rated range or outdoors, otherwise the reliability and life of the Ultrasonic Sensors will decrease.

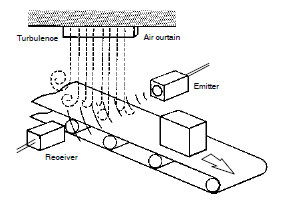

The Ultrasonic Sensors utilize the air as a beam transmission media. Do not use them in places with radical convection or extreme local temperature changes. For example, if there is a hot air curtain that causes turbulence within the sensing area, the Ultrasonic Sensors may malfunction.

The jetting sound of air nozzles includes noise of a wide frequency range, which will affect the operation of the Ultrasonic Sensors. Do not use an air nozzle near them.

The sensing distance of the Ultrasonic Sensors will decrease if there is any water drops on the surface of the emitter or receiver.

The reflective model may not detect any objects if there is any object absorbing sound, such as powder and cotton, on the surface of the emitter or receiver.

The Ultrasonic Sensors cannot be used in a vacuum or explosion-proof area.

Do not use the Ultrasonic Sensors in a vaporous place because non-uniform steams cause difference in temperature and therefore measurement error is observed.