How much does wind affect E4PA Ultrasonic Sensor?

The Ultrasonic Switch uses air as the translation medium, so it is easily affected by wind. Care must be taken when using this Sensor but the E4PA is the least affected by wind out of all the OMRON Ultrasonic Sensors.

For example, wind produced by a 50-cm industrial fan at the highest level will hardly change the analog output.

Effect of wind

Testing conditions: Temperature: 23.5°C, Humidity: 54%

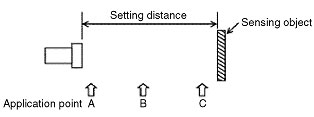

| Distance (m) | Application point of wind | Output Value (mA) | ||

| A | B | C | ||

| Near detection surface | Middle | Near sensing object | ||

| 0.8 | ○ | ○ | ○ | 4.027 |

| 1 | ○ | ○ | ○ | 4.520 |

| 2 | ○ | ○ | ○ | 7.741 |

| 3 | ○ | ○ | ○ | 10.802 |

| 4 | ○ | ○ | ○ | 13.826 |

| 5 | ○ | ○ | ○ | 16.889 |

| 6 | ○ | ○ | ○ | 19.990 |

○: Output not affected by wind

Testing method

1. Initial setting is 0.8 M - 4 mA, 6 M - 20 mA for a flat board (standard sensing object).

2. Set the sensing object at each setting distance and turn ON the fan. Check if the output changes when wind is applied with the fan.

Testing conditions

Power supply: 24 VDC

Sensing object: Flat board (standard sensing object), 100 x 100 mm

Fan: Industrial fan (50-cm diameter) strongest setting

Testing equipment

24 VDC: KIKUSUI, MODEL PAB32-1.2A No.139

DMM: IWATSU, SC-740 No. MO18