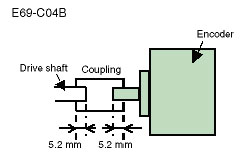

How far should the shaft be inserted into the coupling?

The hollow section (corniced part) near the center of the coupling absorbs vibration and prevents Rotary Encoders becoming damaged due to vibration. To protect Rotary Encoders from vibration, insert the shaft into the coupling at least to the length given in the following table.

| Coupling model | Insertion |

| E69-C04B | 5.2 mm |

| E69-C06B | 5.5 mm |

| E69-C08B | 6.8 mm |

| E69-C10B | 7.1 mm |

| E69-C68B | 6.8 mm |

| E69-C610B | 7.1 mm |

| E69-C06M | 8.5 mm |

| E69-C10M | 10.5 mm |